Benefits of Mig Welding

This gas mixture is easy to use giving good weld. The only difference between MIG welding wire and TIG welding wire is the way they are packaged.

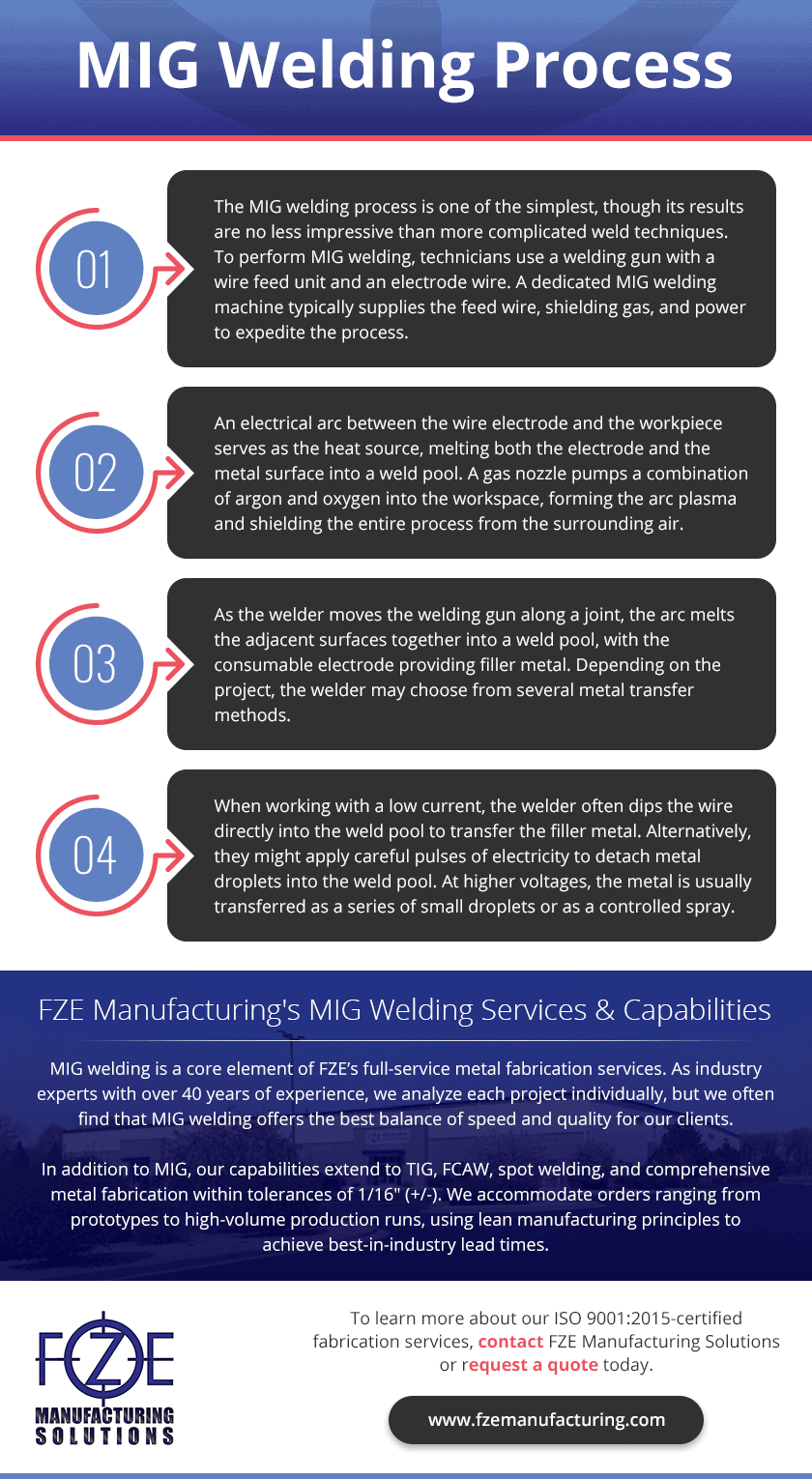

Mig Welding Guide Fze Manufacturing Solutions Llc

From automotive parts to fabricated structures shipbuilding metal buildings and sheet metal applications all have often reaped benefits from the switch to MIG wire.

. But before you can even start schooling to get this certification youll need to be a certified commercial diver which requires 5-7 months of full-time schooling. Lightweight cable and ergonomic design handle is 15 to 30 lighter than competitors Threaded tapered front end welding cosumables improve welder access and fume capture. This can allow an operation to standardize all weld cells with larger-diameter wires which typically offer.

The Cons of Welding Unions. During the welding process many coatings and paints are broken down. To find out which Accredited Test Facility is convenient for you and.

Direct extraction protects welders breathing zone and plant air quality. Using the right filler metal ensures strength and durability producing long-lasting weld joints. Advantages include slag free welding with less clean up even in multiple pass operations.

From about 1952 the process became popular in the UK for welding aluminium using argon as the shielding gas and for carbon steels using. With pulsed MIG welding its possible to use larger-diameter welding wire. Since TIG welding does not use any flux the designations are pretty simple.

MIG welders can also be used for the flux-core welding process which is also wire-fed. Box 397 Sharon Center OH 44274 T. The technique creates a permanent weld and is excellent for the fusion of two materials.

Metal Inert Gas MIG welding was first patented in the USA in 1949 for welding aluminium. Just like any other welding process the filler wire for TIG welding has a designation coding system. The AWS Certified Welder program allows you to test to those procedures used in the structural steel petroleum pipelines sheet metal and chemical refinery welding industries.

Browse a variety of top brands in MIG Flux Core Welding such as Klutch Lincoln Electric and Hobart from the product experts. Stainless steels including a grade 304 or grade 316 can be welded to a plain carbon steel using metal arc welding MIG or tungsten arc welding TIG welding. A step-by-step guide to reading and applying welding symbols.

The technical aspects of welding and equipment as they relate to sales distribution and manufacturing. Welding offers a variety of advantages including the following. Seven courses to help you prepare for the CWS Instructor-led Seminar and exam.

Some non-union members feel that non-union work allows greater rewards for individual contributions and performance than. This is because the lower amperage better controls the current allowing a larger wire to be used on the same material thicknesses where normally a smaller-diameter wire would be required. In terms of costs this method is quite economical in terms of materials fabrication and.

Metal Inert Gas MIG welding and Metal Active Gas MAG welding process numbers 131 and 135 respectively in accordance with ISO 4063 are both variations of the Gas Metal Arc Welding GMAW process which they are more commonly referred to as in USA and some other countries. Argoshield 16 MIG Welding Gas Mix used for MIG Welding Steel. Gas metal arc welding GMAW sometimes referred to by its subtypes metal inert gas MIG and metal active gas MAG is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metals which heats the workpiece metals causing them to fuse melt and join.

Flux-core welding is most efficient for use outdoors as the flux-cored wire shields the arc from contamination such as dirt or wind. A stick welder works on steel stainless steel nickel-based alloys chrome regular steel and aluminum. When welding there is an abundance of heat being used on metals and alloysThis heat can cause the metal.

Union welding members must adhere to union rules and may sometimes be given a job that they do not have an interest in. Avoid wasting time walking back and forth to the welding power source with the Miller MDX-250 EZ-Select MIG Gun. MIG Welding Wire for TIG Welding.

Along with the wire electrode a shielding gas feeds. Welder Unions fit on their members behalf to ensure that welders are paid fairly and have suitable benefits. It has all the benefits of the MDX-250 MIG Gun plus it lets you select from up to four weld programs just by tapping the trigger.

MIG welders are capable of. For over 30 years American Weldqiup has been a leading manufacturer and world-wide supplier of quality MIG welding torches consumables and robotic peripherals. To help avoid errors LED lights on the handle let you.

Benefits of Welding. These fumes are hazardous and lethal. Customer Care 1-800-222.

During this decomposition carbon dioxide carbon monoxide and hydrogen chloride are produced. To be an underwater welder youll need a wet welding D36M certification from the American Welding Society. When productivity matters every second counts.

When welding chromoly move slowly so as to not shock the metal. High-flow design collects more smoke than other fume extraction guns at the weld arc. Thermal breakdown of coatings.

However MIG welding is recommended due to the different melting temperatures of the different steels because it uses a filler material to connect the different steels. The arc and weld pool formed using a bare wire electrode was protected by helium gas readily available at that time. 1375 Wolf Creek Trail PO.

Due to arc shielding welding speed and portability flux-cored welding is the preferred process for construction purposes. All-purpose shielding gas used for MIG welding steel used in general fabrication of carbon steel typically in the 4-12mm range. These use heat created from an electric arc between a consumable metal electrode.

In addition there is a provision to test to a company-supplied or non-code welding specification. Youll learn the basics of underwater welding during this initial schooling but you wont be certified to. XFUME MIG Guns Features and Benefits.

In most cases you can use MIG welding wire. While all of this may seem to push a do-it-yourself welder toward a TIG or MIG welding machine you should consider all the options and how you want to use the welding machine. In addition MIG requires lower operator skills levels than stick or TIG.

Argoshield 16 MIG welding gas mix used for MIG welding with ArgonOxygenCO 2 shielding gas blend.

Mig Welding Advantages And Disadvantages Mig Welding Compare Between Tig And Mig Welding Youtube

No comments for "Benefits of Mig Welding"

Post a Comment